TimberFish Technologies

- Climate Change Problem

- TimberFish Ecotechnology

- Ecologically Integrated Agriculture

- Global Application Program

- Sustainability Program

- TimberFish Table Top Unit

- Photo History

TimberFish Ecotechnologies

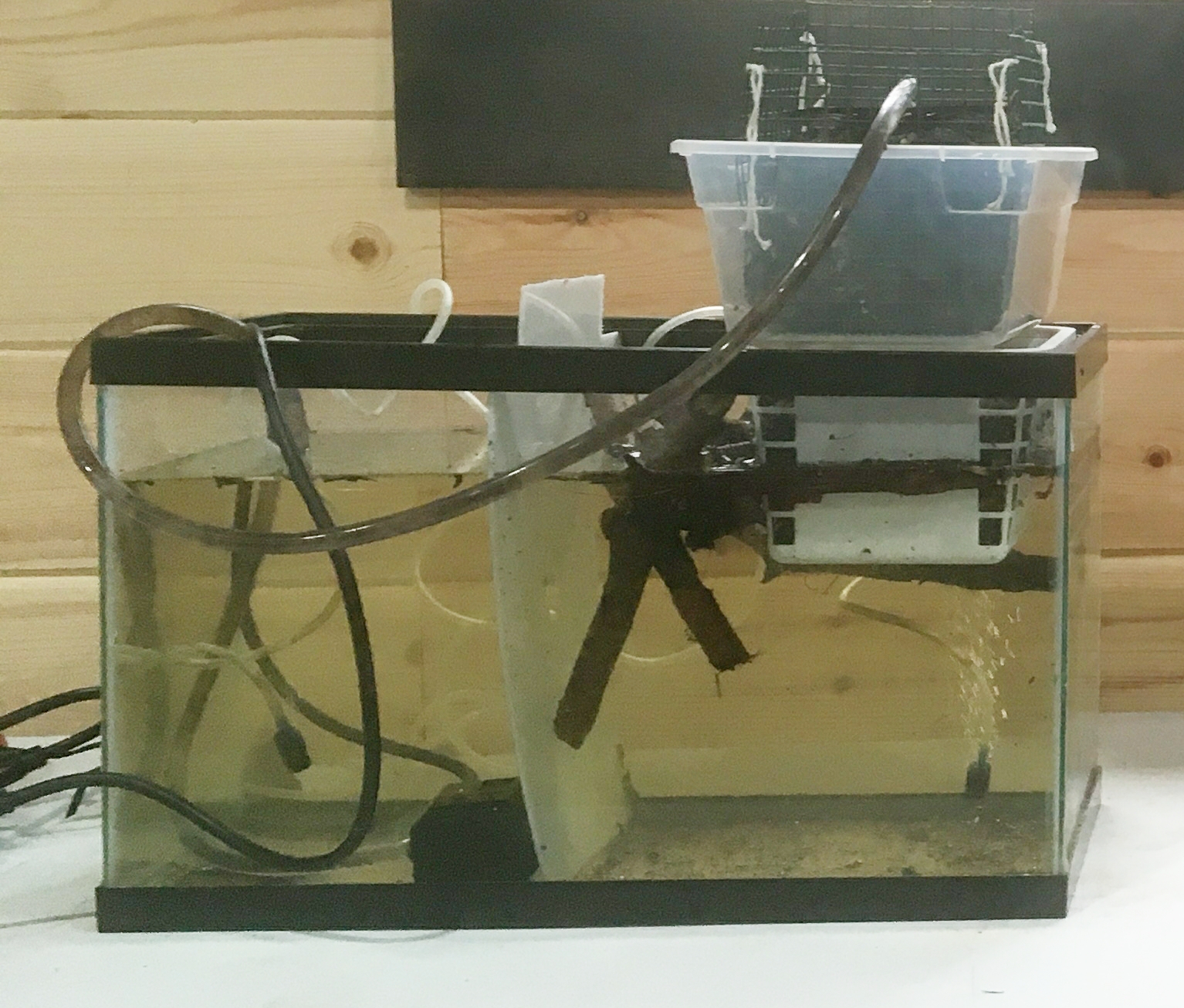

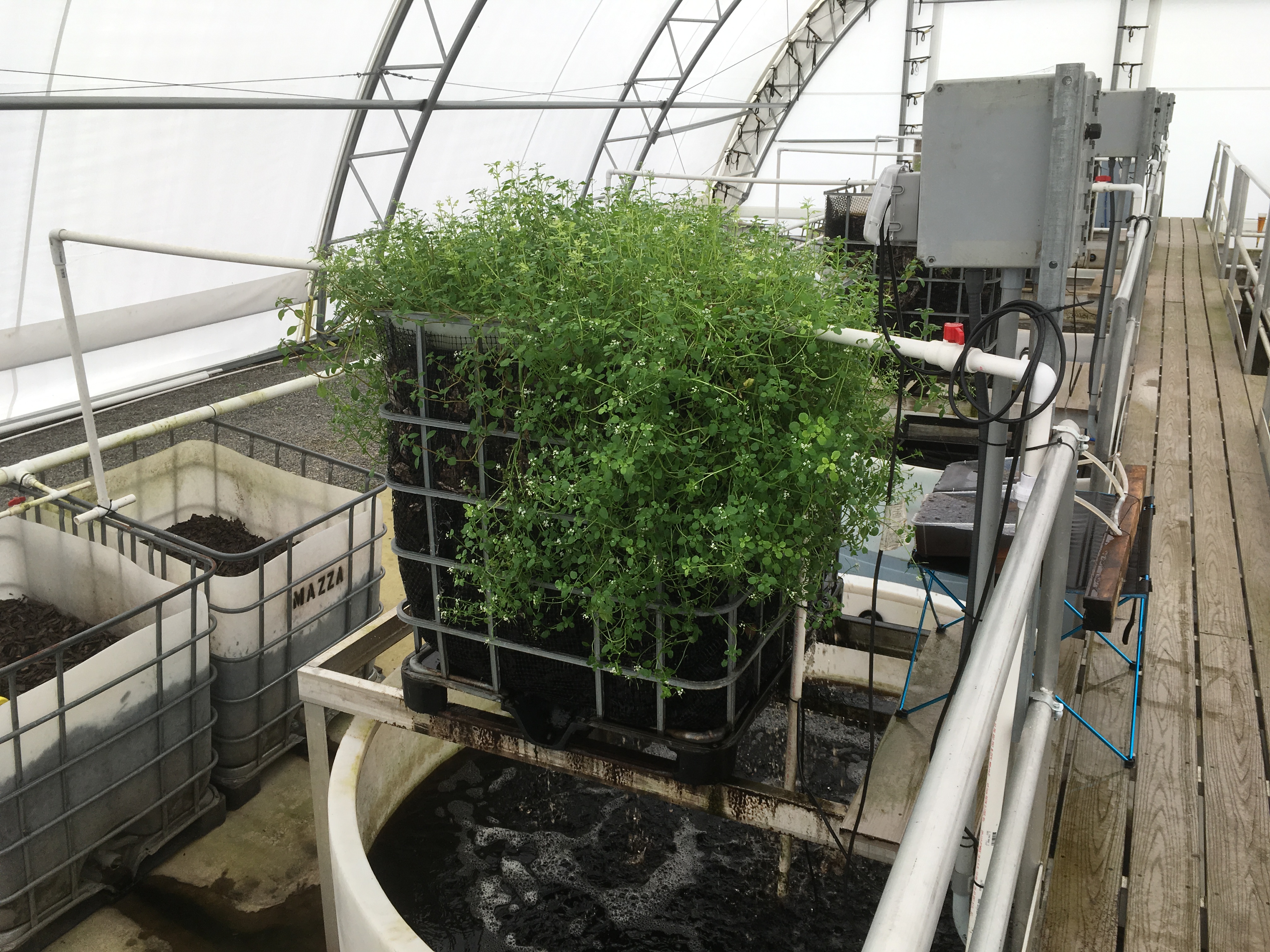

TimberFish has developed an applied ecotechnology system for a global sustainable future for humanity and our planet. The following series of documents will describe who we are and how our program can be understood and implemented at levels ranging from individual table top educational units to large scale forestry based production systems. Here are two pictures of our systems.

|  |

TimberFish LLC. is a New York State corporation, incorporated on September 3, 2008, and doing business as TimberFish Technologies. It is a technology development company that offers environmental ecotechnologies for application in the commercial aquaculture industry or use in educational institutions or programs.

TimberFish is seeking supporters, collaborators, partners, and customers, to get involved with this technology. Direct participation and operation at even the smallest levels will lead to an understanding of how the ecotechnology works; how it can be implemented locally to produce seafood, clean water, renewable energy, and organic soils; and how this can be scaled into a large sustainable domestic aquaculture industry that provides jobs, food, and a better environment for local economies throughout the world.

To achieve this goal TimberFish has recently completed its second generation technology which has expanded and evolved our initial biotechnology process into a self sustaining, self regulating ecosystem structure. This generates a production ecotechnology that is modular, scalable, and adaptable to a wide variety of environmental localities, commercial opportunities, and desired seafood products.

The TimberFish Ecotechnology will utilize a given bioregion’s natural biology for the local and sustainable production of food and energy as the basis for community and economic development. It comprises a series of aquaculture systems that embody and demonstrate how natural ecosystems work. Here the production of seafood from plant material and nutrients occurs within an environment that allows for self selecting and harvesting of the natural foods which the product seafood would normally eat. This preserves the overall balance, stability, and health of the production ecosystem.

The core of this process is that microbes will grow and reproduce by consuming the cellulose in the wood chips and the nutrients. Invertebrates will consume the microbes. Fish will consume the invertebrates. Microbes will then consume more cellulose in the remaining wood chips and will use the nutrients in the invertebrate and fish wastes to make more microbes. The process cycles as long as there are periodic inputs of wood and nutrients accompanied by the harvesting of fish. When most of the cellulose has been removed from the wood the residual chips are harvested as a high energy substrate for renewable energy production. There is no waste.

Because the process is modular and scalable TimberFish systems can range in size from 10 gallon table top aquarium units to multimillion gallon commercial facilities. They include:

TF1 basic tank ecotechnology system, 500 to 1,000 gallons.

TF2 raceway ecotechnology system, 2,000 gallon modules.

TF3 custom and specialty units.

TF4 commercial production systems.

TF5 table-top aquarium and basement or garage models.

If you are interested let us know. There are lots of options available and we would like to work with you. The rest of this document includes summaries of representative systems for each of the categories listed above. At the end are Appendices which provide additional detailed information. These are available documents that can be provided upon request.

All of these are open production systems that are integrally connected to their local environment. They require at least periodic inputs of water, plant material, and nutrients, and they periodically produce outputs of product animals, organic soils or fertilizers, renewable energy substrates, and high quality water effluents. They can also serve additional primary or secondary aesthetic, educational, or recreational purposes.

We believe that this involvement will lead to the implementation of the larger systems described herein. We are committed to continuing research and development programs in conjunction with colleges, universities, and businesses to further support and expand this technology on a global level.

To promote this technology we are publishing these documents to enhance the public understanding of ecological principles. Here are photos of a model pattern for a TF5 table-top unit, a TF1 tank unit, a TF2 outdoor pond unit, a TF3 mobile trailer mounted unit, a TF4 40,000 gallon commercial system, and a diagram of a potential multi million pounds of fish per year Ecologically Integrated Agriculture unit combining a dairy farm with aquaculture. Summary descriptions, illustrations, and examples of these and other potential applications are included below.

|  |

|  |

|  |

Here is an introductory video,

Here is a 27 minute tour of the TimberFish facility at the Five & 20 Spirits & Brewing facility in Westfield, NY

There are many additional photographs of the development of this ecotechnology. Many of these can be seen in the Photo History.

These include The Microbial Tank Farm, Bion Environmental Technology Systems, Basement/Garage Systems, Woodland Pond Systems, Woodland Tank Systems, The Freshwater Institute Field Trial, The Mobile Trailer Unit, and the Five & 20 System in Westfield, NY.

And finally here is a 2025 case study in which a conventional backyard goldfish pond, with a basement holding tank for winter, was converted into a second generation TimberFish ecotechnology system.

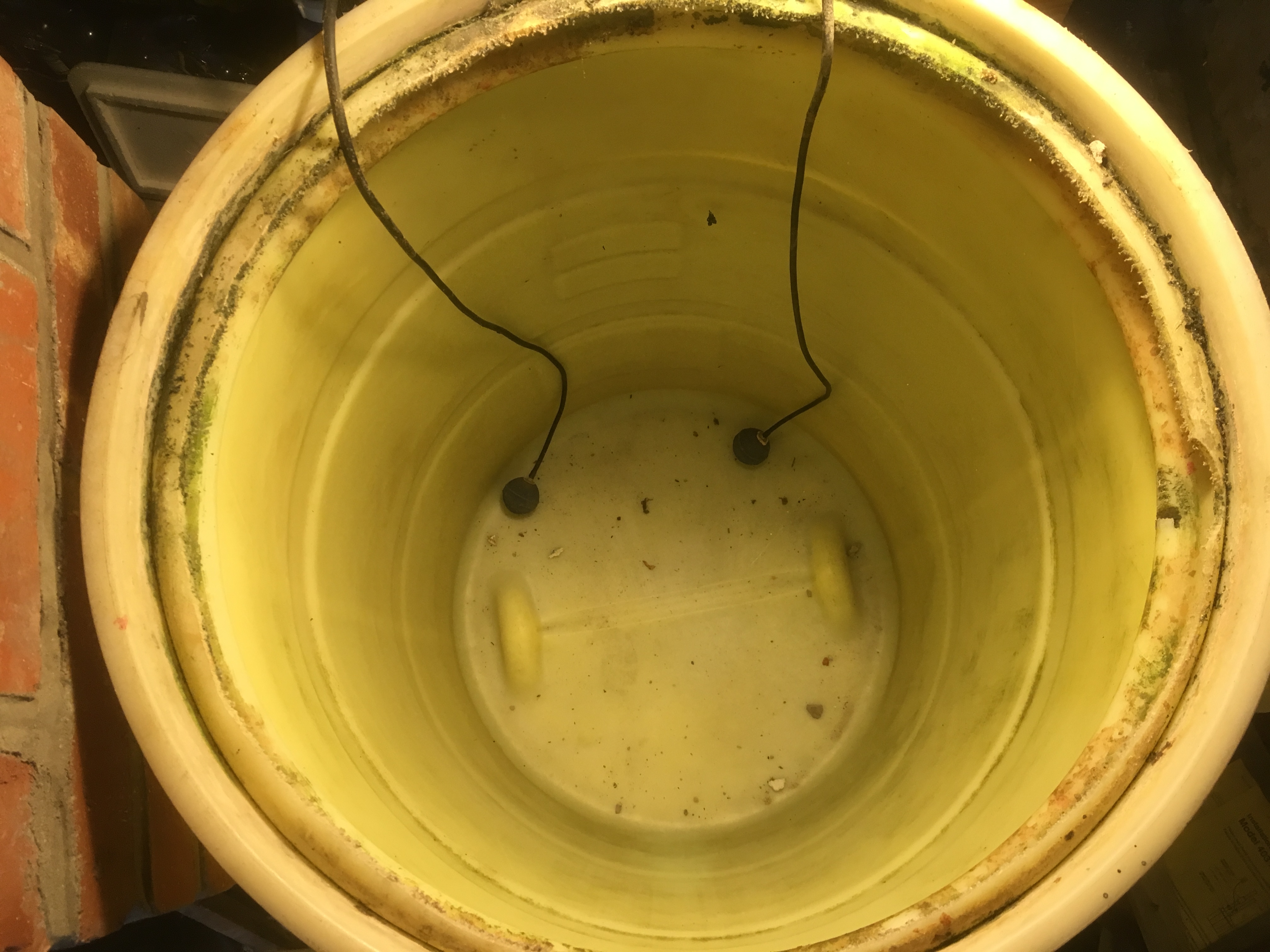

The backyard pond comprises an eight foot diameter hexagonal concrete tank that holds about 400 gallons with a water depth of 18 inches. There is a three foot diameter center island that supports a bird bath and some moss covered rocks. Water is pumped from the pond, up though the birdbath pedestal, and into the center of the birdbath, where it functions as a fountain that spills over the edge, onto the moss and rocks below, and then seeps back into the pond. Here are photos showing the pond in summer and when most of the water is removed for winter. This shows the detail of the center island.

|  |

The suction of the recycle pump is attached to a circular biofilter containing a plastic media that traps biosolids. These are periodically removed from the biofilter and deposited on the groundcover near trees on the property. Here are three photos of the pond and the birdbath fountain and biofilter.

|  |  |

Here are photos of the biofilter components and the plastic media.

|  |

Pond water enters the biofilter through the holes in the top, passes through the plastic media, and exits the biofiter through an outlet at the bottom of the filter. This is connected to the recycle pump which pumps the filtered water up to the birdbath fountain. An extensive microbial biomass grows on and in the plastic media and this also traps the suspended solids in the influent water.

The fish are fed a commercial fish feed which contains the organic carbon and hydrogen materials which the fish need for energy and synthesis, and the nitrogen (N) and phosphorus (P) and other elements needed for healthy growth. When the fish eat the feed they retain only 20 to 30 percent of the N and P and the rest is excreted back into the pond water. Most of this excreted N and P will be captured in the microbial biomass living in the biofilter and this will then be removed from the system when the biofilter media is periodically cleaned. This removed N and P will then be land applied on the property as a fertilizer for trees, grass, and other vegetation. The N and P that is excreted as solid waste directly in the pond is removed from the pond when it is cleaned out after the fish are removed for the winter. These solid wastes are also then land applied.

The pond freezes over during the winter and for this time period the fish are removed and put in a 55 gallon drum in the basement. The drum is aerated and a small recycle pump circulates water through a small biofilter attached to the side of the tank. Water is exchanged at a rate to maintain a hydraulic retention time of 15 days. The effluent water is siphoned off from the bottom of the tank and this contains the solid wastes from the fish. This water goes into a holding wash tub and is pumped into our septic tank. Soluble and suspended solids are trapped by microorganisms growing in the biofilter. Periodically the biofilter is washed and the microbial solids that have grown in the biofilter are discharged into the holding wash tub and then pumped into the septic tank.

In the summer of 2025 the backyard pond was converted into a second generation TimberFish ecotechnology system. The biofilter was replaced with a bundle of dead sticks from 30 to 36 inches long that were collected from the sugar and red maple trees on the property. A second biofilter containing shorter sticks was constructed from hardware cloth that fitted into a black four gallon milk crate. Here are photos of these two systems.

|  |

In middle of August, 2025, the old biofilter was removed from the pond and the two new filters installed.

|  |

The suction line for the recycle flow to the birdbath fountain was placed just under the edge of the stick bundle. I Prior to this the goldfish had been periodically fed but after a few weeks this feeding was essentially stopped. Because the pond had developed a small leak makeup water was added occasionally. This amounted to about 10 gallons per day for a Hydraulic Retention Time (HRT) of about 40 days. No solids or sticks were removed from the pond.

An unexpected consequence of all this was that the fish spawned and starting in September baby fish were observed living in and around the stick bundle. This had occurred a few times in the past 25 years when more vegetation was in the pond and this had allowed for the maintenance of a fish population in the pond ranging from 3 to 12 fish. These fish would be brought into the basement 55 gallon system each winter to prevent loss from the pond freezing solid.

In late October and early November 2025 the basement system was retrofitted to make it consistent with the second generation ecotechnology. As previously described the system had comprised a 55 gallon tank with two small air stones and a small recycle pump and biofilter. About 2 to 5 gallons of water per day would be siphoned off the tank bottom and replaced with tap water. The HRT was thus 10 to 20 days. This included any solid fish wastes that collected there. This water went directly into a wash tub that was pumped into our septic tank. This biolfilter could be replaced or washed every few weeks or so with the collected solids also going into the tub and septic tank.

To retrofit this system a new stick ecosystem sticking out of a two gallon milk crate was constructed . Here are photos of the 55 gallon drum with air stones, the new stick ecotech system in the two gallon red milk crate, and the stick ecotech system in the 55 gallon drum.

|  |  |

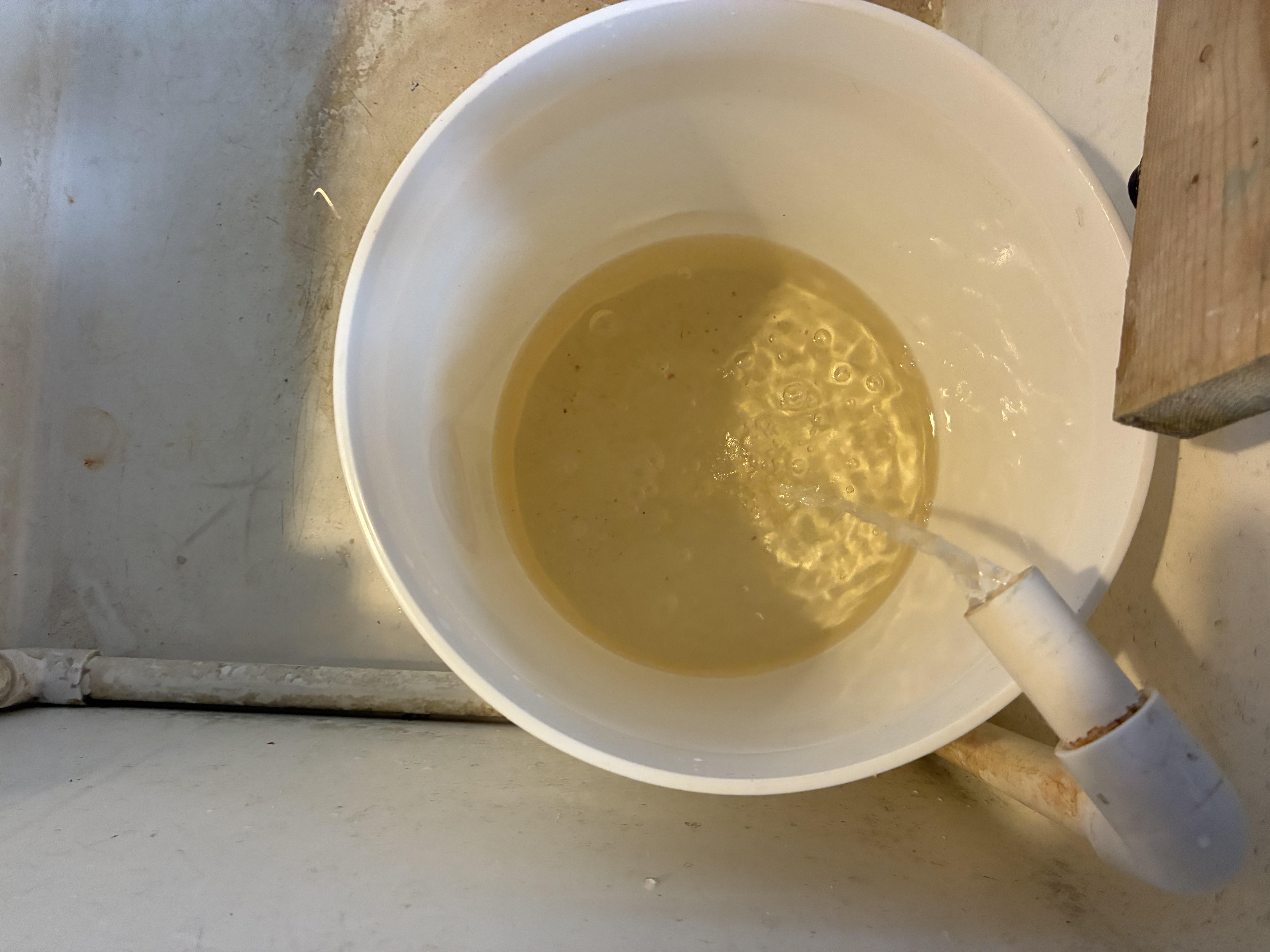

The stick milk crate unit was placed on two bricks so that an airstone could be placed under the milk crate. A five gallon pail was then filled with the sticks from the milk crate system from the pond. Holes were drilled in the bottom of the five gallon pail so that water could flow through the short sticks in the pail, and then flow out of the pail onto the larger stick system that was submerged in the 55 gallon drum. The five gallon pail was placed above the water line in the 55 gallon drum, but still on top of the submerged stick system. This was continuously irrigated with a recycle pump from the bottom of the drum. Here are photos of the pail with holes in the bottom, the pail placed above the submerged stick system in the 55 gallon drum, and the 2 gallon decant pail system inside a wash tub that receives water and solids siphoned from the bottom of the 55 gallon drum. These are subsequently pumped into a septic system.

|  |  |

Every day about two gallons of fresh water are added to the drum in a manner that flushes solids out from under the submerged stick system. These are then siphoned off into the decant pail in the wash tub for pumping into the septic tank. Most of this water is poured off the top and a cup or two with the settled solids are returned to the top of the perched five gallon system.

Here is the completed system.

|

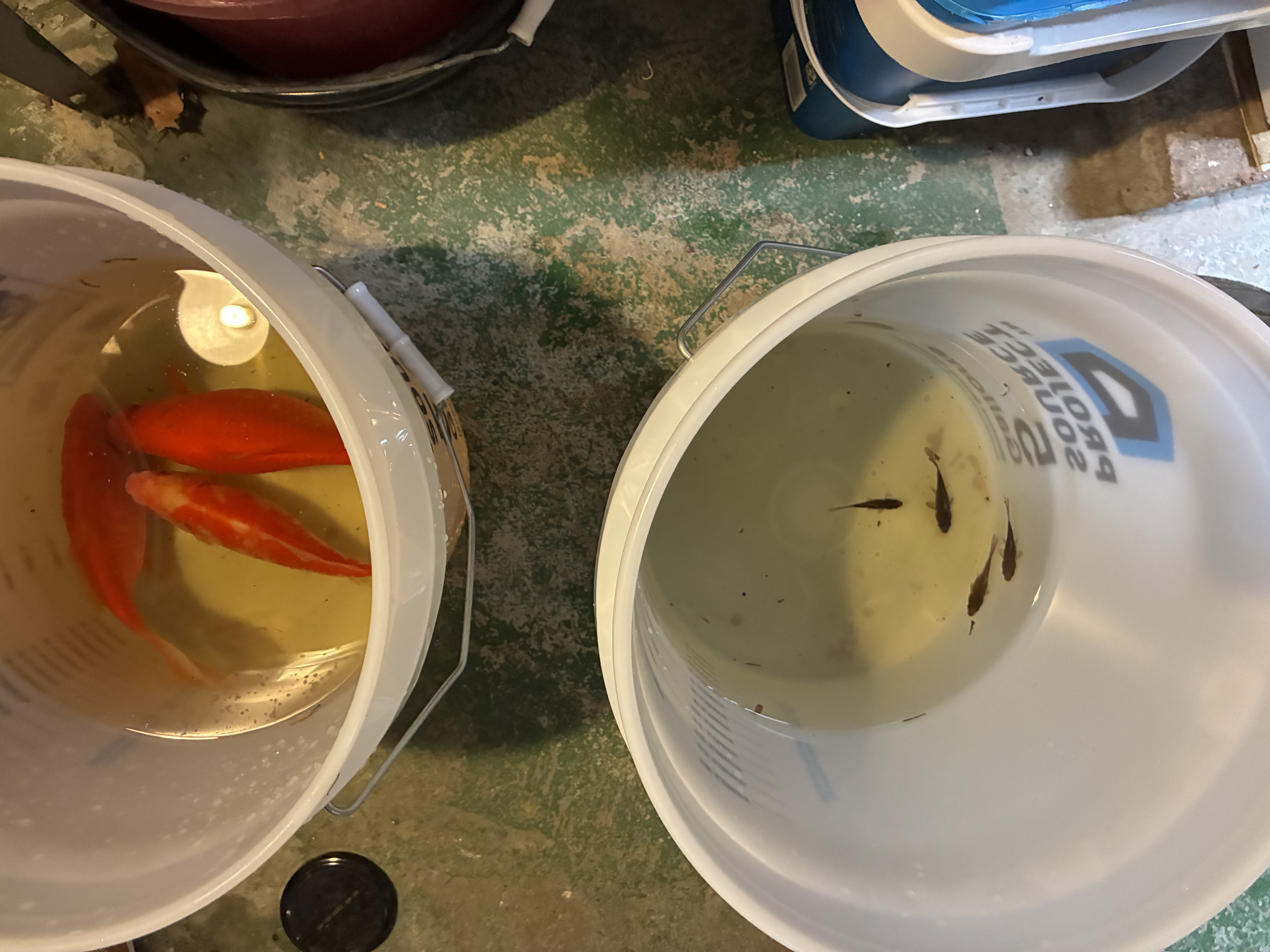

Here is the initial stocking of goldfish from the pond on August 16, 2025. This included three large goldfish that had been in the system for many years. They collectively weighed about 2.5 pounds. They were accompanied by four baby goldfish that were born in the system in early September, 2025. Over the next several weeks 8 more baby goldfish were collected from the pond and introduced into the basement system for a total of 12 new baby goldfish.

|  |

Here are photos of some of these baby goldfish in the system on January 8, 2026.

|  |

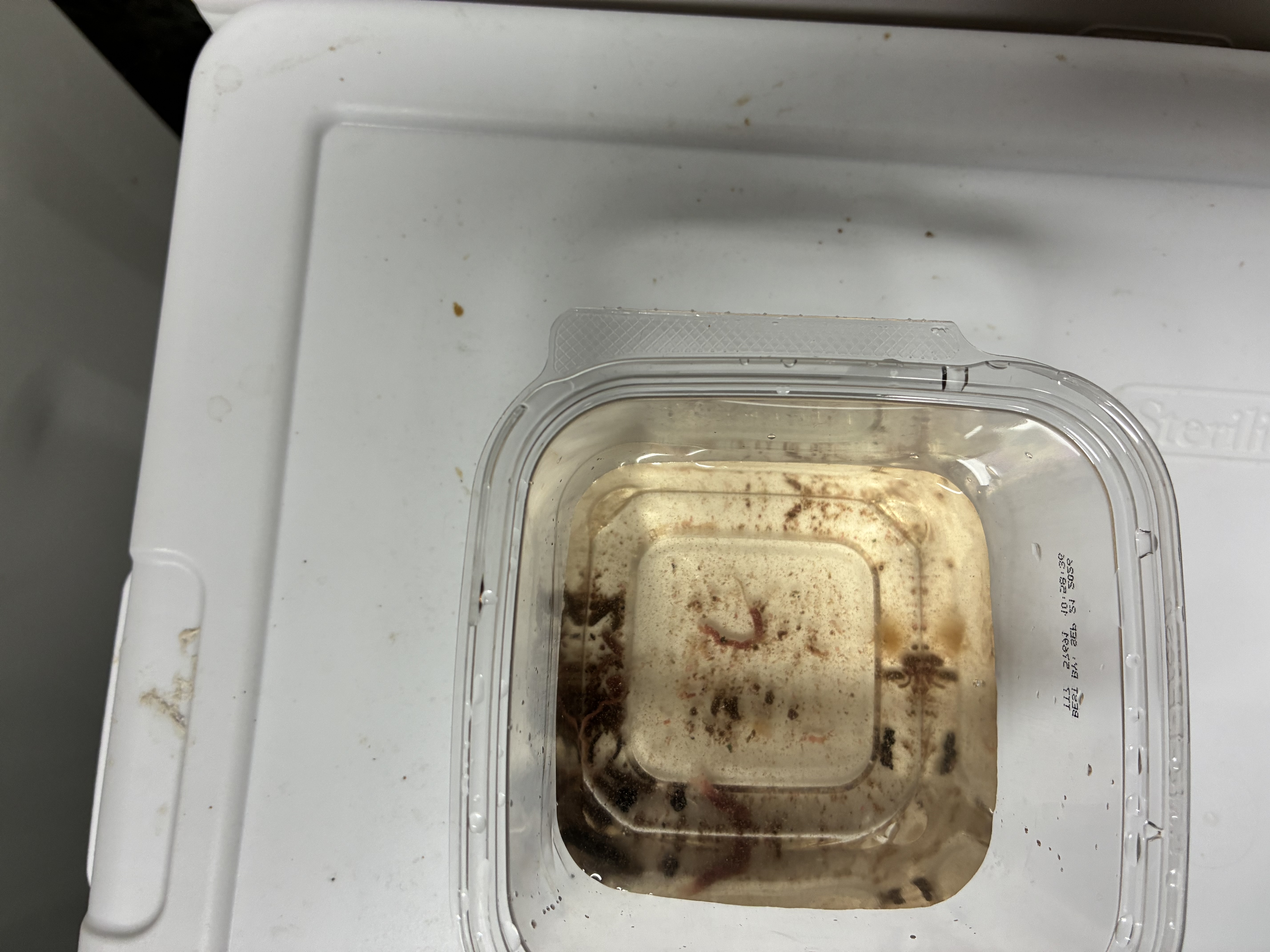

Here are photos of the decant pail being filled by the siphon; the decant pail and collected wastes, biomass, and wood fragments after the siphon is finished; and the decant pail after almost all of the water has been emptied with only the solids and about two cups of water remaining.

|  |  |

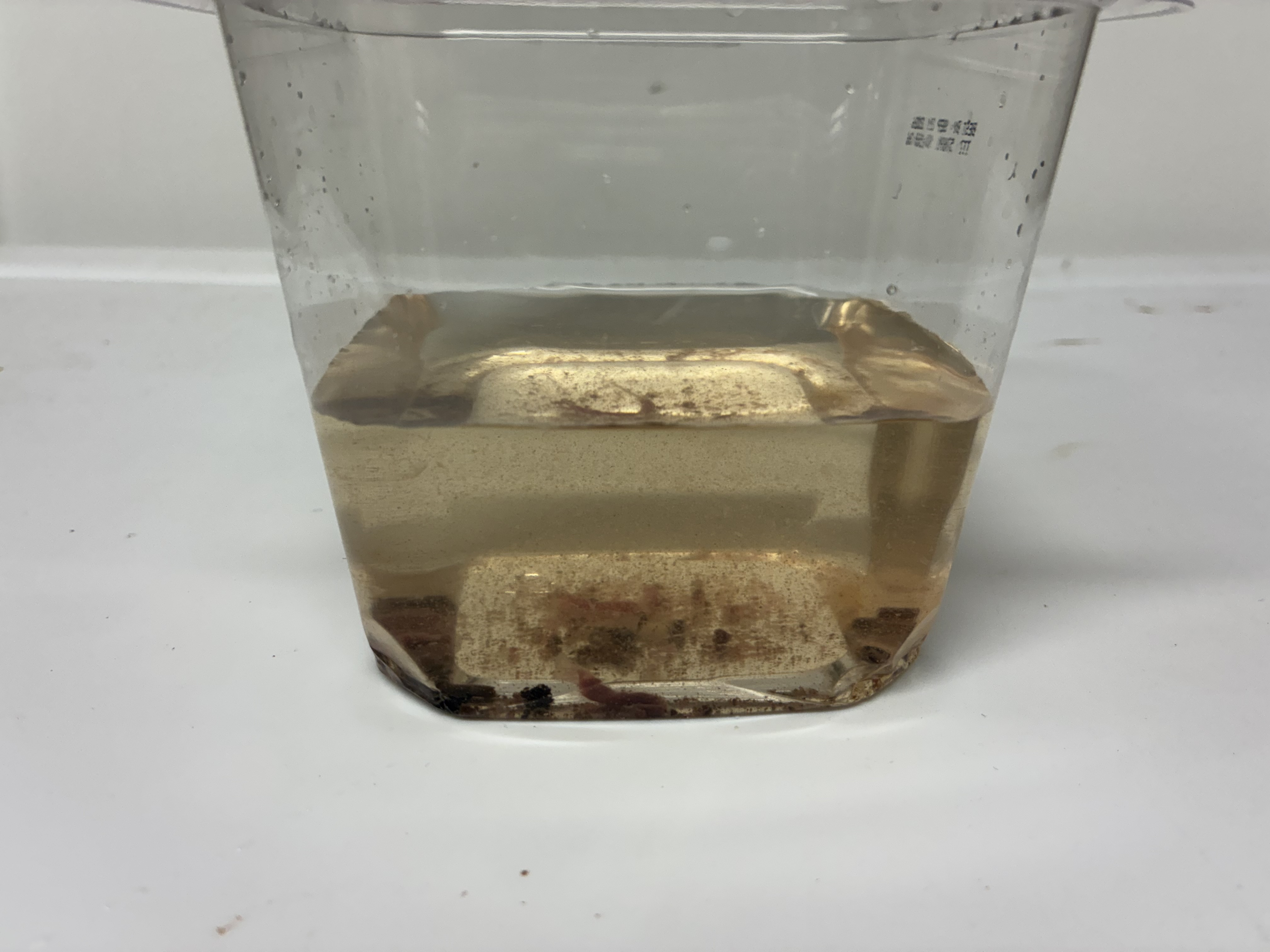

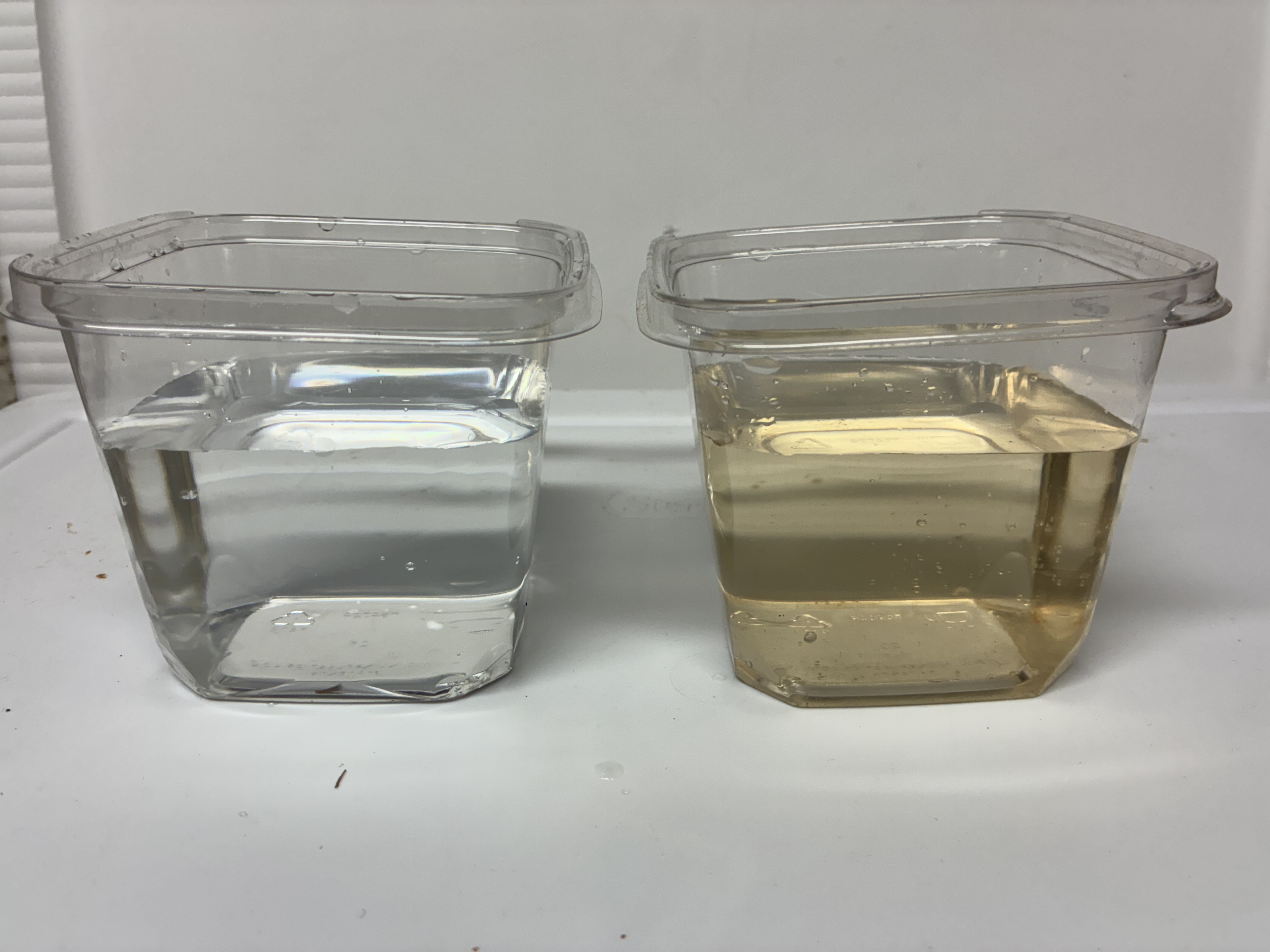

The collected solids and remaining water is transferred into the perched 5 gallon pail. Here are two more views of these settled solids and wastes and a comparison with tap water and the decant water in the last photo

|  |  |

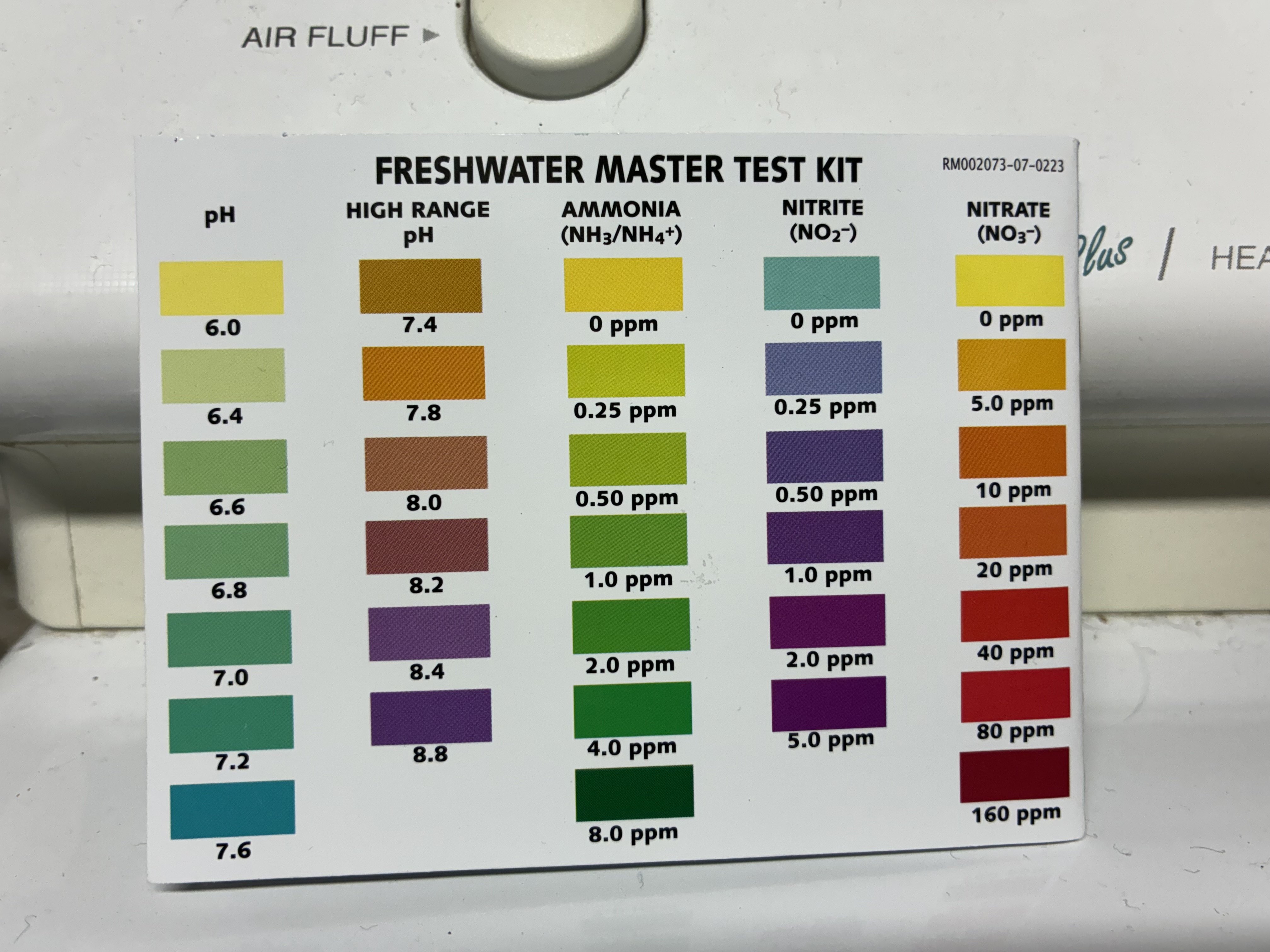

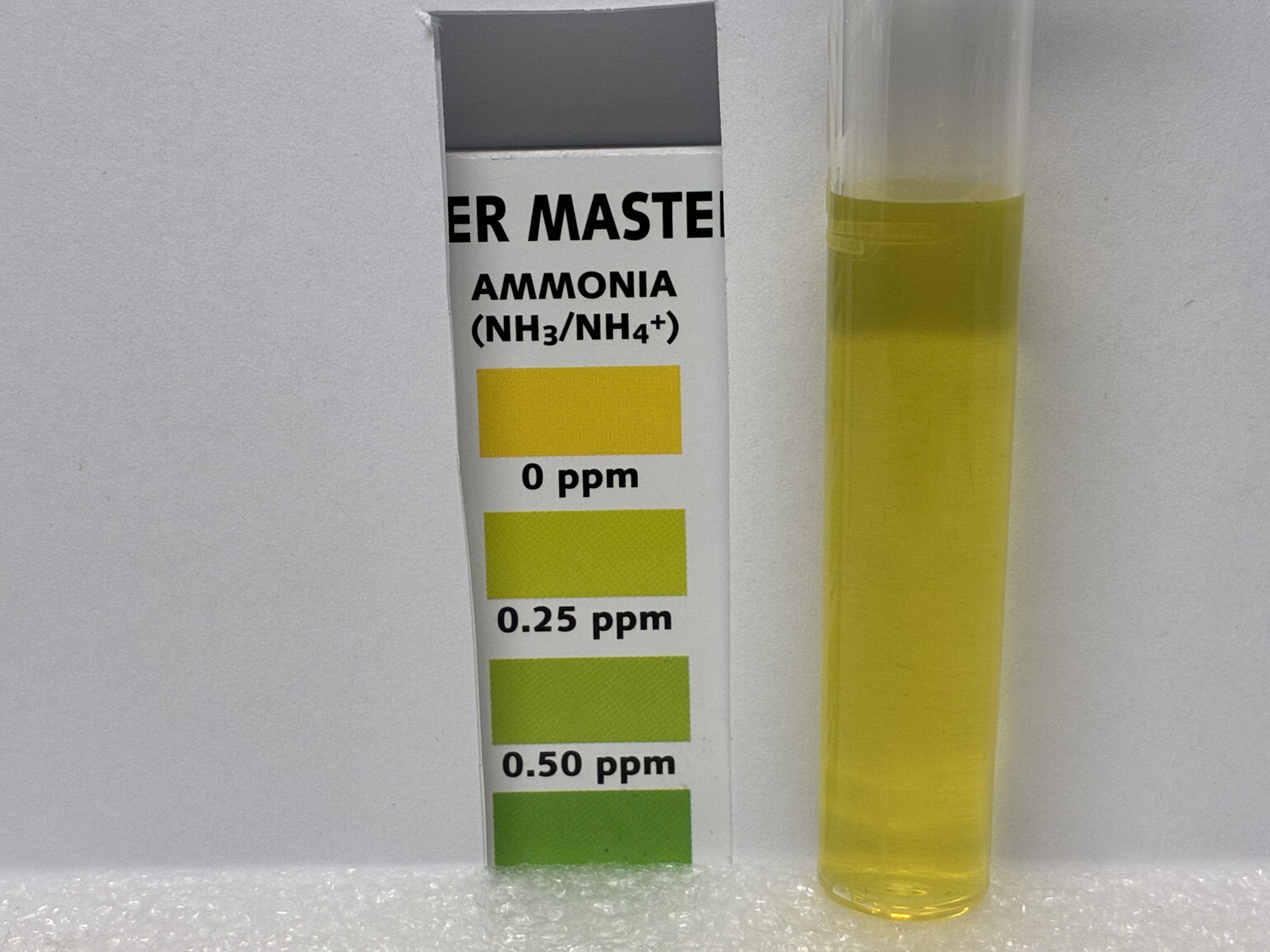

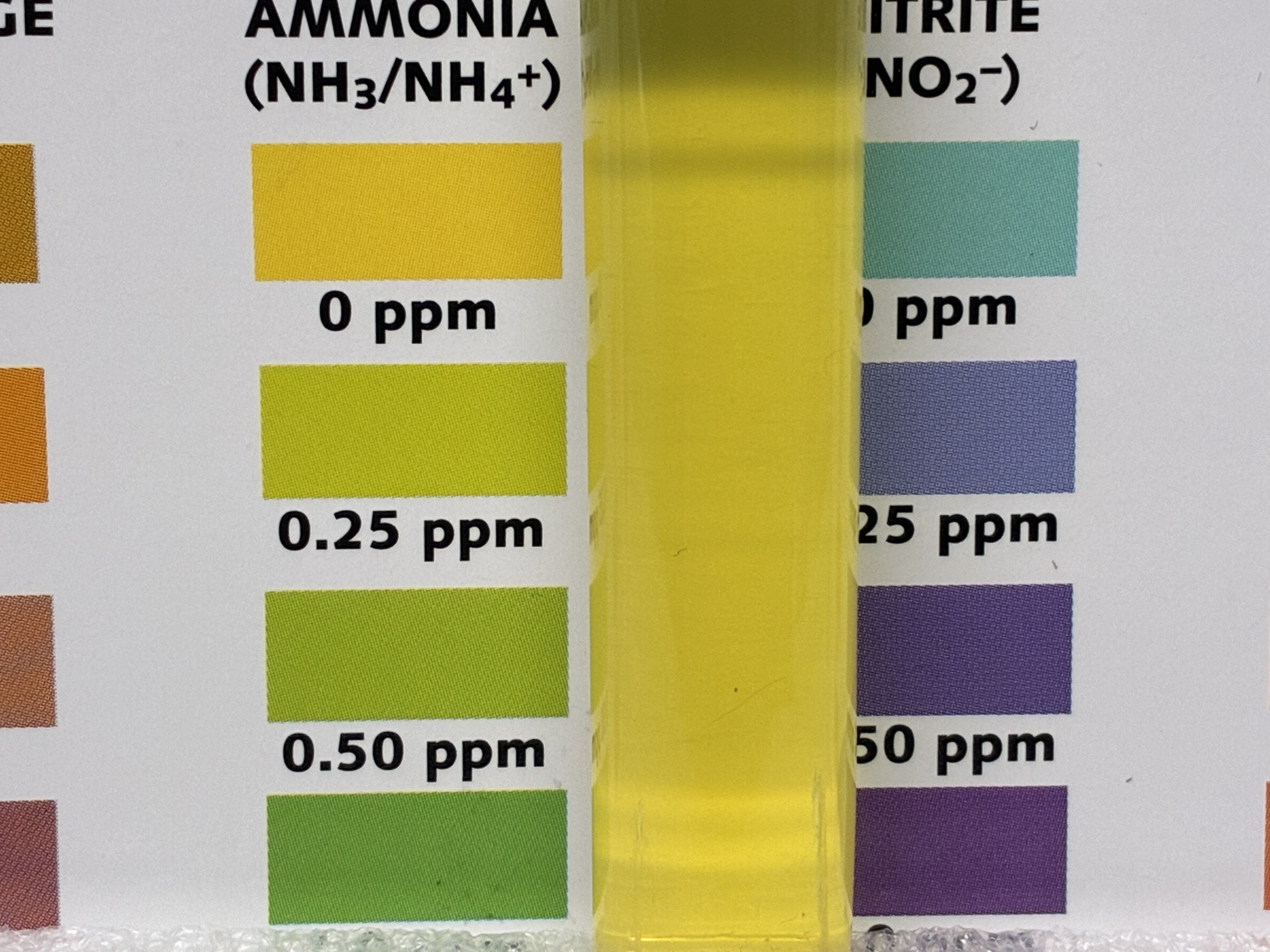

Periodic testing of the decant water for ammonia has shown no detectable ammonia. This can be interpreted as less than 0.25 mg/l according to a freshwater master test kit that is being used to track ammonia. Here are photos of the test kit analytes and the ammonia results for January 10, 2026.

|  |  |

The following pages contain summary descriptions, illustrations, and examples of other possible applications of this ecotechnology. More details are presented in the Appendices listed at the end of this document which are available upon request.

Basic process description and specification:

The TimberFish Ecotechnology can convert small amounts of nitrogen and phosphorus and a dry weight ton of wood chips, sticks, or saplings without leaves, into 35 to 40 pounds of wet weight fish. This will also produce 500 pounds or more of a residual wood product with a high lignin content suitable for renewable energy use, and several hundred pounds of potting soil, organic fertilizer, or soil amendment. The latter will depend on the amount of excess nitrogen and phosphorus initially available. See Appendix A for more detailed description of the technology.

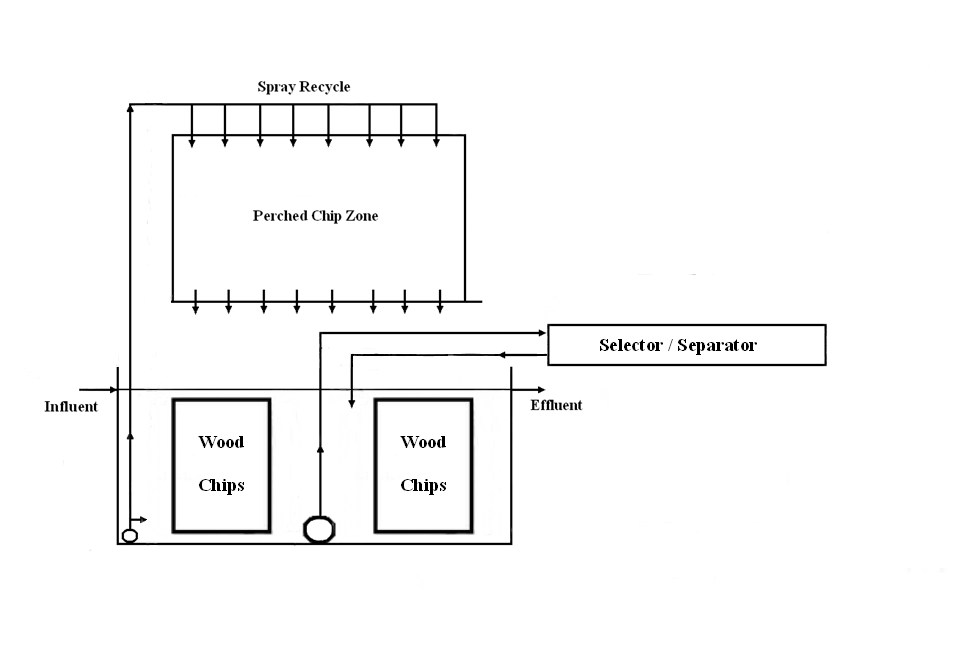

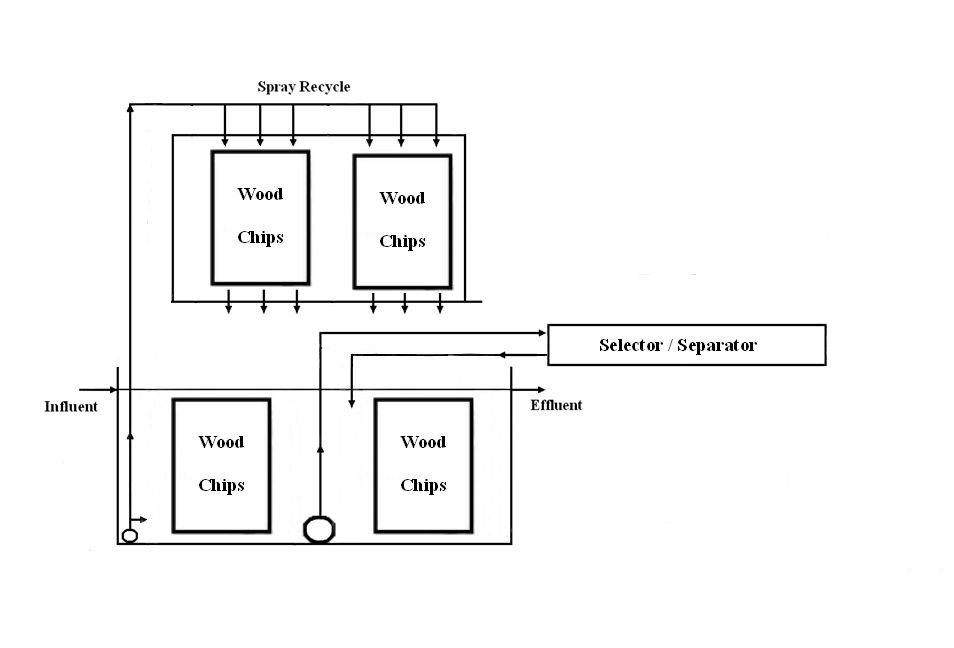

TF1: This is our basic introductory system. It is contained in and above a 1,000 gallon circular tank that is 8 feet in diameter and 31 inches tall. There is a 4 foot by 4 foot by 4 foot cube perched above the tank which contains wood chips or baskets of wood chips as in the example of TF1. This cube is irrigated with water from the tank which flows through the wood chips and back into the tank below. There are other wood chip baskets within the tank and a two part solids collector/ organism selector that can be located next to or as part of the in tank cube system. Fish are free to swim around the submerged chip baskets and feed on the biofloc and invertebrates that grow on and in the submerged chip baskets, or fall in from the perched chip basket and selector units.

The system requires a water source and drain, electrical power, aeration, pumps, and a support structure to provide access to all components of the system. It also comes with a test kit and instruction manual. The 1,000 gallon tank can be buried in the ground or placed at ground level. Here is a diagram of a typical TF1 unit.

The TF1 unit is basically an indoor unit in that it needs protection from freezing temperatures and other environmental impacts. The unit can be located in a garage, barn, laboratory, green house or comparable structure. In temperate climates or for seasonal operation units can be located outdoors where they can be a part of ornamental gardens or parks.

If space is limiting a smaller 500 gallon version is available. This can show structure, process, and fish raising ability, but is generally too small to demonstrate quantifiable fish production capability.

See Appendix B for how the general specifications are implemented in TF1, and a startup and operations manual.

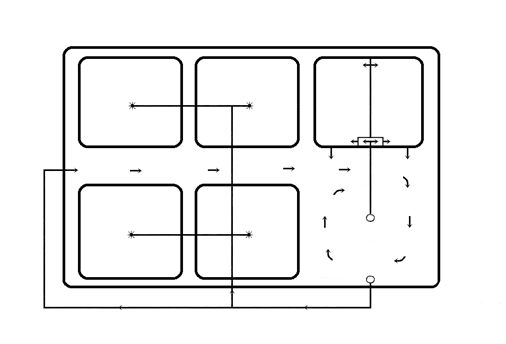

TF2: These are larger outdoor units with similar structural subsystems and process dynamics as TF1. They will be contained in inground tanks or ponds with additional trays or baskets on top. This will often look like a raised bed garden with vegetables, or flowers, or other ornamental or useful and attractive vegetation. These units will be structurally similar to the first generation flow through bioreactors. But these units now will contain submerged chip baskets that allow flow past and around the units so that fish have access to the chip basket submerged surface area as a source of feed. See Figure below:

A typical process module will often be contained in a 10 ft by 8 ft precast concrete raceway that is 3 ft deep and closed at both ends. This would contain four submerged 3 ft by 3 ft by 3 ft cubes which will hold chips and an additional 3 foot cubed area that will contain a two part solids collector / organism selector unit. This basic unit could produce 50 to 100 pounds of fish or seafood per year.

In this embodiment flow will not be forced through the chip baskets as was the case with alternating wood chip and aeration zones in first generation systems. See Appendix C for specifications and an instruction manual for TF2.

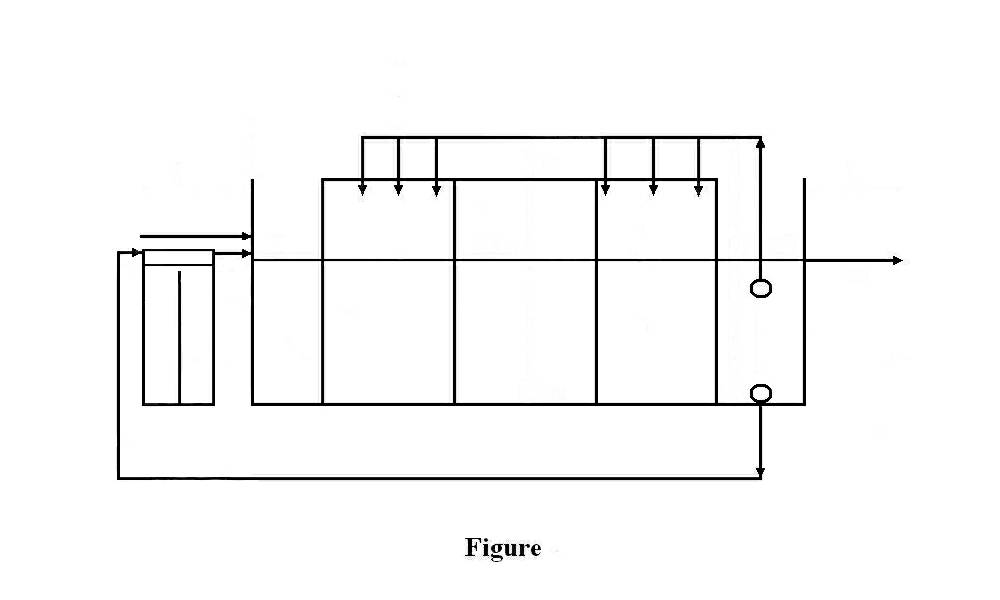

TF3: These are custom combination units that can serve a multiple of additional uses. They can comprise our mobile unit and our hybrid willow raceway system. For example, TimberFish has just introduced its Hybrid Willow Sapling Raceway Unit which comprises an 8 foot by 10 foot precast concrete rectangular tank that is 3 feet deep. There are three water zones and two zones containing hybrid willow saplings. The saplings will be contained in wooden crate structures that are 8 feet long, 3 feet wide, and 3 feet deep. The saplings will be 8 feet long and placed lengthwise in the crate structures. Wood side bars will keep them in the crate structures.

Water will enter an influent water zone, pass through a first sapling crate into a second water zone, then through a second sapling crate into an effluent water zone, from which it will be discharged. A recycle pump will pump water and settled solids from the bottom center of the effluent water zone and will distribute this to the tops of the two sapling crates. The following drawing presents a diagram of side view of this system.

Fish will live and grow in the three water zones and will be able to pass through the sapling zones in transfer tubes. They will feed on the biofloc and invertebrate organisms that grow in the sapling zones. Most systems will have additional recycle flows and a solids collector / organisms selector system next to or above the raceway.

This configuration using crates for the saplings is designed for relatively low Hydraulic Retention Time (HRT) applications. For high HRT application the crates can be replaced by bundles of saplings.

See Appendix D for details, specifications, and links for the mobile demonstration unit and the hybrid willow sapling raceway unit.

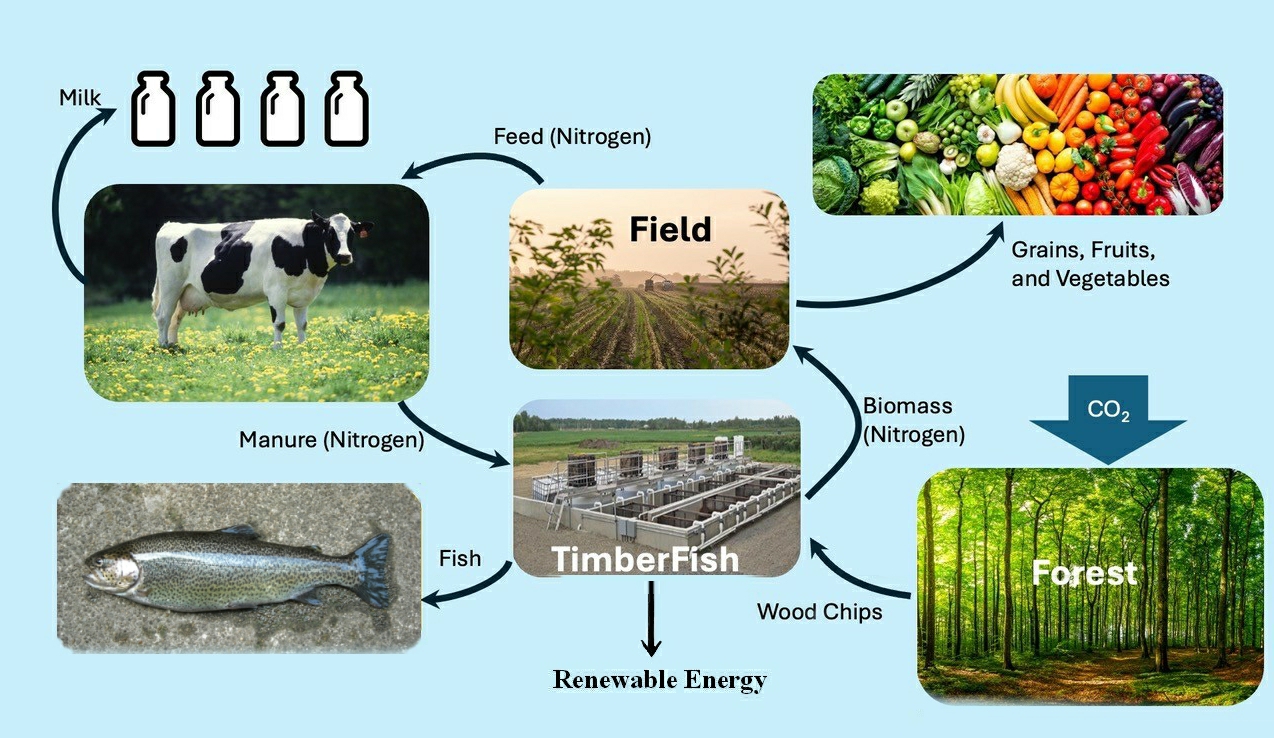

TF4: Commercial Systems. These will comprise applications of the diagram shown above. Detailed descriptions can be found at Ecologically Integrated Agriculture

TF5: Table Top Aquarium and Basement or Garage Models. TimberFish will provide technical information for anyone who wants to build their own system.

The Table Top Aquarium and Basement or Garage Models provide a way for everyone to understand this technology by actually operating a working system in their home, or classroom, or virtually any other locally available space in their neighborhood or community. The interaction with the Model will generate an understanding of ecological thinking and how that can lead to resolving Climate Change and other environmental problems.

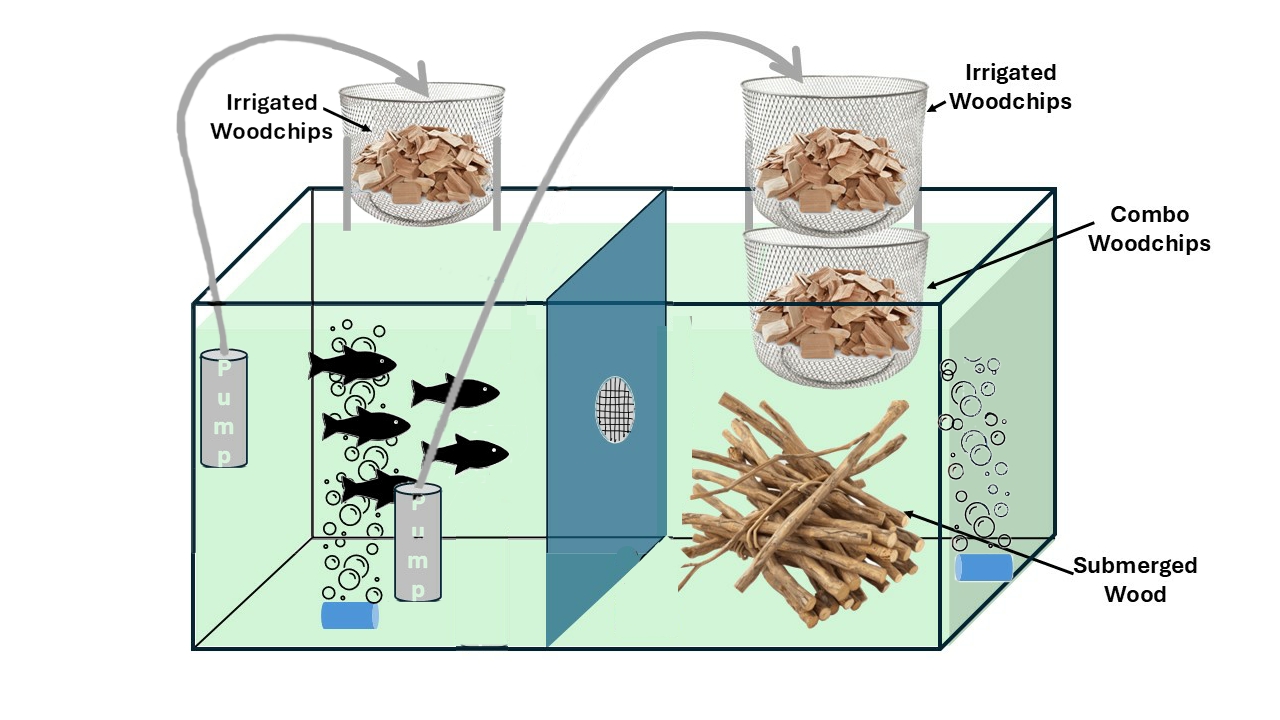

The Aquarium Models usually comprise 10 to 20 gallon aquariums with three or four ecoreactors and aeration and pumping systems

Here is a conceptualized diagram of such a unit.

The Basement or Garage Models usually fit in a 55 gallon drum or comparable container. They comprise a contained wood chip or stick zone in the container, an aeration unit, and a siphon arrangement to periodically remove settled solids from the bottom of the container and save them in a collector. This will occur when makeup water is added to the container.

Detailed descriptions and operational procedures for Table Top Aquarium and Basement or Garage Models are provided in Appendix F.

In addition TimberFish will continue to seek collaboration with educational institutions ranging from high schools, to colleges, and universities. These could start with the Table Top Aquarium and Basement or Garage Models and then scale up to include the small systems described as TF1, TF2, or TF3.

For more information on our educational sustainability program see Appendix G.

Finally, our ultimate goal is to see a global sustainable aquaculture industry that can provide an additional food source to feed future populations without infringing on or compromising existing agricultural practices.

Thus TimberFish will continue to pursue involvement with major corporations and NGOs. Here is a summary of this opportunity. The US consumption of seafood (fish and shellfish) is slightly less than 20 pounds per person per year, or about one 6 ounce serving per week. To meet this demand the US currently imports 70 to 85 percent of its seafood, and over half of these imports are produced from aquaculture. However, only about one pound of our domestic seafood production comes from US aquaculture, and that has a value of about one billion dollars per year.

Because of the significant nutritional value of seafood TimberFish believes that in the future an increased availability of locally and sustainably produced seafood could result in an increase in US consumption up to two 8 ounce meals per person per week. This would represent an additional 30 pounds of seafood per person per year for a total annual seafood consumption of 50 pounds per person per year. This could be achieved by building ten thousand land based TimberFish Recirculating Aquaculture Systems, each producing a million pounds of seafood each per year. It would represent a 30 billion dollar per year new industry. The TimberFish Ecological Aquaculture Forestry Platform provides the ecotechnology foundation to make this industry possible.

Appendix H includes the full TimberFish Business Plan for this opportunity.

APPENDICES: These describe additional details as are linked, shown below, or are available upon request.

A. General Process Description and Specification for all Systems. See Appendix A below.

B. A specific application to TF1. See Appendix B below.

C. Specifications for TF2.

D. Descriptions of some of our custom combination units. See trailer and our Hybrid Willow Raceway Unit

E. Commercial Systems. Includes Ecologically Integrated Agriculture

H. TimberFish Opportunity Business Plan.

EXAMPLE DOCUMENTS:

Appendix A: General Process Description and Specification for all Systems.

The TF Ecotech system is based on the following concepts which describe how microbes can convert wood and nutrients into invertebrates and fish. Consider wood in the form of dry wood chips, sticks, or saplings without leaves. For purposes of illustration we assume that a ton of dry weight wood contains 1,000 pounds of cellulose, 400 pounds of lignin, 400 pounds of hemicellulose, and 200 pounds of ash.

In an appropriate aquatic environment, and with at least one pound or more of nitrogen and at least 0.3 pounds or more of phosphorus, the microbes and invertebrates can convert 1,000 pounds of mostly cellulose and some hemicellulose and ash into 35 to 40 pounds of wet weight fish. The lignin and some of the hemicellulose can be extracted as a high energy residual suitable for renewable energy production. The remaining hemicellulose with minor amounts of cellulose and lignin can be combined with a residual microbial biomass to produce a potting soil, an organic fertilizer, or a soil amendment. This latter distribution depends on the amount of excess nitrogen and phosphorus are available in the process, either from the wood, or added to the aquatic environment as feed or other forms of nutrients.

The system itself will comprise the following structural elements:

Contained water volume, tank or pond, that is suitable for raising product aquatic organisms. These will usually be fish but may also be other aquatic vertebrates such as turtles or amphibians, or they may be various macroinvertebrates such as crustacea, mollusks, snails, etc. In this discussion we assume that the product animal will be a fish and that the containment unit will be a fish tank.

Submerged wood chip baskets which are contained in a mesh or screen structure that allows a microbial biomass and accompanying invertebrate populations to be exposed to direct contact with the product animal, fish.

Irrigated perched wood chip baskets that are usually placed above the tank such that water from the fish tank can be pumped to the top of the perched baskets and allowed to flow down through the wood chips so that it reenters the fish tank.

A reversible two part collector/selector unit that is usually a tank, tray, barrel or similar structure dived into two connected regions. Thus water containing settled solids from the fish tank will be pumped into the first zone of the collector/selector. Overflow from this first zone will flow by gravity into the second zone. Overflow from the second zone will flow or be pumped back into the fish tank. When the first zone is half full of settled solids flow will be stopped. The solids will be pumped out, and flow will be resumed but now it will go into what used to be the second zone. From there it will overflow into the former first zone and go back to the fish tank.

Multiple water pumps will be used to maintain water flow through various recycle loops within the system. Also a blower or air pump system will provide aeration to various locations within the system.

System Configuration:

The basic system structural elements will be arranged in a particular application to satisfy the following criteria.

Maximize the availability of screened wood chip basket surfaces for fish access.

Maintain a flow pattern throughout the system that allows for settling of solid fish wastes and biofloc in specific areas so that they can be efficiently removed by periodic pumping and sent to the collector/selector.

Allow for some water flow and invertebrate movement through the submerged wood chip baskets.

Allow for easy supplemental addition of wood chips to the submerged and irrigated wood chip baskets to maintain a constant wood chip inventory within the total system.

Biological Components:

Generally all of the biological organisms used in a given system will be native to the bioregion in which the system will operate. This will include the trees that provide the wood chips as well as the local fish that live in the areas’ streams, lakes, or ocean. Once one or two product fish are chosen the search and selection of additional organisms will focus on what are the natural foods for the fish.

These will usually include the terrestrial earthworms and aquatic oligochaete worms found near or in the natural habitat for the fish. For freshwater systems crayfish, freshwater snails, and small minnows are useful. Local insects and insect larvae are also candidates if they are easy to cultivate and deliver to the system.

Process:

The process involves tracking the carbon (C), nitrogen (N), and phosphorus (P) elements as they enter, move through the recycle loops, and leave the system. It begins with the wood chips and whatever N and P is contained in the wood chips. This is then supplemented by an external source of nutrients. Often this will be a commercial fish feed designed for the product fish to be grown.

The fish will use the carbonaceous materials in the feed to provide the energy for the fish growth and assimilation of N and P into the body of the product fish. But this is not a very efficient process and a majority of the N and P consumed is excreted in both solid and liquid form.

There is not enough carbon in the excreted fish wastes to bioconvert the excreted N and P back into a microbial biomass. However, the wood chips provide the extra carbon needed to capture the excreted N and P and incorporate them back into a microbial biomass. This drives an additional food chain for more fish production.

Tracking the movement of the C, N, and P through a steady state operating system requires measuring or calculating the mass of each element that enters the system and when this occurs. Comparable measurements or calculations then describe the distribution function for each element in the various solid and liquid components of the system This will include the biological organisms, unused inputs such as the wood chip inventory, uneaten fish food, excreted wastes from fish and other organisms, non soluble suspended and settled solids, and total dissolved solids.

Finally, all C, N, and P that exits the system needs to be measured or calculated. This includes the elements in the product animals, the partially degraded residual wood chips, all harvested and removed settled solids, all dissolved and suspended C, N, and P in the system effluent, and all gaseous emissions. The latter will be almost all carbon dioxide. Other greenhouse gases such as nitrogen oxides, ammonia, reactive organic gases (eg. acetate), etc. should be absent and this can be verified when necessary or desirable.

Process control: For large systems this will comprise measuring water quality parameters such as temperature, Dissolved Oxygen, pH, ORP, salinity, conductivity, alkalinity, TDS, TSS, TVS, and chemical parameters such as TKN, Total Phosphorus, cBOD, COD, TAN, Nitrate, Nitrite, ammonium ion, and orthophosphate. Lignin, cellulose, and hemi cellulose concentrations in raw and residual wood chips will also be useful.

For small systems a basic pond water test kit for temperature, pH, salinity, ammonium ion, and ortho phosphate can suffice. DO is useful but not always necessary if excess aeration is supplied.

Process Control algorithms and procedures are available for individual applications. In general, we will use a feed for trout with a 3 to 1 N/P ratio. Then we will try to maintain a pH of 7.0 and an ammonium ion to orthophosphate ratio of 4 to 1 in the fish tank.

Harvesting:

Once a system is adequately populated with microorganisms and invertebrates it can be operated so that fish are removed in either a batch or intermittent steady state mode. When this occurs some of the wood chips will be removed as well.

Batch mode: A target fish size is selected and the free water volume (tank water volume minus the submerged chip basket volume) will be stocked with a given number and weight of small fish. This will be determined so that when the surviving fish (initial stocking minus expected mortality) reach the target fish size, the carrying capacity of the free water volume will be equal to some target fish biomass density. All fish will then be removed and some fraction of the submerged and irrigated wood chips may also be removed.

The system can then be recharged by bringing the wood chip inventory back to its initial state and restoring the microorganism and invertebrate populations to their earlier levels.

Intermittent steady state mode: This will be for a system that already has established microbial and invertebrate populations. A working number of fish will be stocked and allowed to grow. Some of these initially stocked fish will be harvested once they reach one of several targeted weights for marketed fish. A target maximum fish biomass density will be chosen and the initial stocking will be such that when the fish biomass density is first achieved, that there will be some fish that meet the smallest of the initial market target weights. Some of these fish will be harvested and the system will continue to operate until the maximum fish biomass density is again achieved. At that point some of those fish that now meet the second target market size will be removed.

This cycling will be repeated until all fish are removed from the system. The system then will be restored to its initial state and restocked for another sequence. Some submerged wood chips will be harvested and removed from the system each time fish are harvested.

The alternating two zone solid collector / organism selector unit will receive the solid wastes collected from the fish raising zones. These solids will be distributed to one of the two selector tanks where the solids will settle out and invertebrate organisms will grow. The overflow will go to the second tank and then back into the main fish growing area. When one solids collection tank is half full the flow pattern will be reversed and the settled solids and invertebrate organisms pumped out of the first tank. The invertebrates will be fed to the fish and the solids will harvested to become an organic fertilizer or potting soil.

Chip harvesting:

The surface of the wood chips is where the initial microbial growth will occur. This is because the microbes need the energy in the wood chip to assimilate the N and P in the water and convert it into a microbial biomass. At the start of this process the composition of the wood chip is about 70 to 95 percent cellulose and hemi cellulose with 5 to 30 percent lignin. As the degradation of the wood chip continues the cellulose goes first and then the hemicellulose is attacked next, and this is accompanied by a decrease in efficiency and microbial growth rate at the surface. The wood chip surface becomes less desirable and microbial turnover and invertebrate predation reduce the microbial concentration at the chip surface.

We try to harvest the wood chips when the degradation has removed about half of the initial wood chip mass. The chip structure is still similar to that of the initial wood chip because its structure is mostly determined by the lignin which will not have been substantially degraded. It is however now much more porus so a simple washing or hosing of the chips will induce the invertebrates to leave, and most of the microbes to be removed from, the chip.

A version of the batch mode can employ some of the steady state harvesting procedures. In this version when the fish reach the target size they will have a total mass of X, but only half of the fish will be removed. The remaining fish will have a total mass of X/2. They will be allowed to grow as before but when the total mass again reaches X, half of the remaining fish will be removed. This will continue until all fish have been removed. Wood chip removal and replacement will be as for the steady state mode.

Appendix B: describes how the general specifications can be applied to a TF1 batch mode. This will be a smaller second generation version of the system that was used in the Evaluation Study performed at the Freshwater Institute in 2010 and 2011. FWIReport

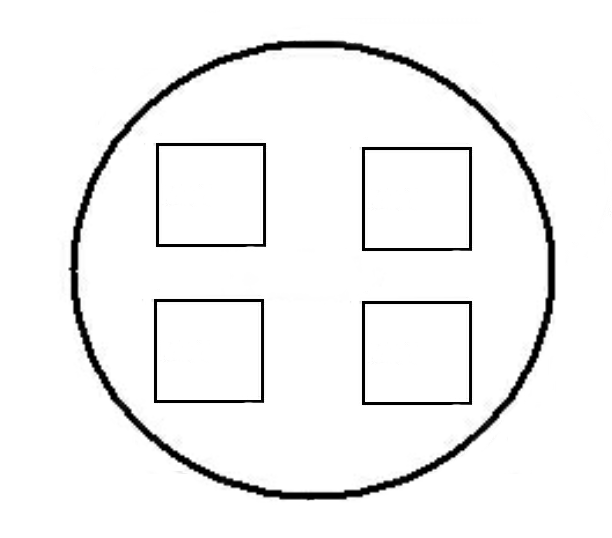

A typical TF1 system is contained in and above a 1,000 gallon circular tank that is 8 feet in diameter and 31 inches tall. There is a 4 foot by 4 foot by 3 foot basket perched above the tank which contains wood chips. These wood chips are contained in four 22 inch by 22 inch by 30 inch smaller baskets placed within the larger basket. All of the four smaller baskets are irrigated with water from the tank which flows through the wood chips and back into the tank below. There are other small wood chip baskets with the same dimensions submerged in the tank and a 100 gallon two part solids collector/ organism selector that can be located next to the in tank cube system. The system requires a water source and drain, electrical power, aeration, pumps, and a support structure to provide access to all components of the system. It also comes with a test kit and instruction manual. The 1,000 gallon tank can be buried in the ground or placed at ground level. Here is a diagram of this TF1 unit.

Here is a diagram is looking straight down at the tank with submerged chip baskets.

Each of the submerged and irrigated small chip baskets will have a volume of 63 gallons and will hold wood chips at a density of 2 pounds per gallon. Thus there will be a total of 504 pounds of wood chips in both the submerged and irrigated baskets for a total wood chip loading of 1,008 pounds, dry weight.

Using the composition and conversion figures from our general specifications (Example A), the 1008 pounds of dry weight wood would contain 504 pounds of cellulose, 202 pounds of lignin, 202 pounds of hemicellulose, and 100 pounds of ash.

In this example the water volume in the tank will be 940 gallons. Subtracting the 252 gallons taken up by the wood chip baskets leaves 688 gallons of free water volume for the fish. Assume that the system will operate with drinking water with a 100 day Hydraulic Retention Time. Thus between 7 to 10 gallons of drinking water will be added to the system per day resulting in an effluent of 7 gallons per day with some evaporation from the system. Since ammonia and phosphorus are not normally regulated in drinking water we will assume a tertiary treatment wastewater effluent water quality standard of 2 mg/ l for Total Ammonia Nitrogen with phosphorus at about 0.5 mg/l for our influent water.

At a basic level we will operate with only test kit measurements for pH, temperature, salinity, ammonium nitrogen and orthophosphate. Thus we will keep pH at 7.0 or lower to ensure a low ammonia (NH3) to ammonium ion (NH4+) ratio so that our ammonium nitrogen measurements will reflect the bulk of the N available. An ammonium ion to orthophosphate ratio will be maintained at 4 to 1.

For the initial run of the batch process load the tank with water and the baskets with wood chips. Once the species of fish are selected, rainbow trout in this example, obtain inoculum sediment and water samples from local lakes, streams, and wetlands for microorganisms and desired invertebrates. For this case the invertebrates should include terrestrial earthworms, aquatic oligochaete worms, and freshwater snails. Local insects and insect larvae are also candidates if they are easy to cultivate within the system. Small minnows may be useful when larger fish are developed.

Run the recycle and aeration systems for a week or two to ensure that aeration and recycle pumping systems are operating smoothly. Then introduce 22 fingerling trout weighing about one ounce each, for an initial stocking weight of 22 ounces. The plan is to run the system for 8 months and then to harvest 20 trout weighing about one pound each. This will occur when the fish biomass density reaches 0.029 pounds of fish per gallon of available water. We expect that there will be two morts, one weighing 4 ounces and a second weighing 8 ounces. Thus at 8 months we will have produced 20.75 total pounds (332 ounces) of fish, containing 0.415 pounds (6.64 ounces) of N, with 20 pounds of fish being harvested consumable product.

We will feed the trout during this first batch process to build up the microbial and invertebrate populations as well as grow the fish. Following the general guidance from the Evaluation Study performed at the Freshwater Institute in 2010 and 2011, we will use a high protein trout chow and will hand feed the fish on a daily basis to no more than satiation. We estimate that our feed will contain on a dry weight basis; 48 percent protein, 18 percent fat, 18 percent carbohydrate, 12 percent ash, 3 percent fiber, and 1.2 percent phosphorus. This feed should result in an average Specific Growth Rate of about 2.5 percent per day yielding a doubling time for total fish weight every two months. That takes a one ounce fingerling to a 16 ounce (one pound) fish in 8 months. In normal aquaculture facilities this would result in a Feed Conversion Ratio (FCR) of 1.0 pounds of dry weight feed to produce one pound of wet weight fish.

Applying a FCR of 1.0 to our TF1 system would indicate that for a total of 20.75 pounds of fish produced we would need 20.75 pounds of feed and this feed would contain 1.66 pounds (26.56 ounces) of N. However, the Freshwater study reported a Feed Conversion Ratio (FCR) in our study of 0.7 so producing 20.75 pounds of fish in our system would only require 14.525 pounds of feed containing about 1.162 pounds (18.59 ounces) of N.

We start the initial run with 1008 pounds of dry wood and we will assume that this will have 0.05 percent N on a dry weight basis. So the 1008 pounds of dry wood will contribute 0.504 pounds or 8.06 ounces of Nitrogen to the system. Also, the initial stocking of 22 one ounce fingerlings (wet weight) would contain 0.44 ounces of N for a total initial load of 8.50 ounces of N. Adding this to the 18.59 ounces of N from the feed yields a total N input to the system of 27.09 ounces of N over the initial run.

The total weight of fish harvested in this run (20.75 pounds or 332 ounces) will contain about 0.415 pounds (6.64 ounces) of N. Subtracting this from the 27.09 ounces of N added to the system will leave 20.45 ounces of N still in the system or discharged in the effluent after the fish are removed. However, the loss of N in the effluent is minimal. An effluent of 7 gallons per day with 2 mg/l of N discharges 0.0000167 pounds of N per day or 0.000267 ounces per day. Over 8 months this amounts to less than 0.065 ounces of N lost in the effluent. So the N that is left in the system after the fish are removed will be about 20.4 ounces. Assuming that all of this will be contained in a microbial biomass it would have required the consumption of about 67 pounds of cellulose. ((20.4/0.12)/16)/0.157 where the 20.4 is ounces of N; the 0.12 is the fraction of a dry weight microbe that is N; the 16 is ounces per pound; and the 0.157 is the pounds of microbes that can be produced from a pound of cellulose. See Example A.

Some of this microbial biomass would be collected in the selector/separator as shown in the first figure. During the operation of the first run, and all subsequent runs, some of the wood chip components will be separated from the wood chips as small particles, and these and some of the solid fish wastes will be collected from the bottom of the tank and pumped to the selector/separator. Some microbial biomass will be collected with them. The small particle fragments of the wood chips will be primarily cellulose and hemicellulose. This will leave the lignin as the primary structural component of the residual wood chip.

The fate of this collected material will be an operator decision and this will impact what will be in the system for subsequent runs. This will also be true for harvesting the wood chip residuals and replacing them with new chips.

Harvesting the wood chips will be done in a manner that removes all invertebrates and most of the microbial biomass from the residual wood chip. Some of the microbes will stay attached to the harvested chip and some of them will be settled out with the small particle fragments and collected in the solids selector/separator.

If a significant quantity of the residual microbial biomass is retained in the system prior to subsequent operational runs this will significantly reduce the need for additional fish feed since most, and sometimes almost all, of the N requirement that the feed usually supplies will be met with the N in the residual microbial biomass. Generally subsequent runs will have retained enough microbial biomass so that they will require only replacement amounts of N for that removed from the system in the prior run. Thus a second run of this TF1 system would probably only need about 5 pounds of feed. This would be in contrast to the 14.5 pounds required for the first run and the 21 pounds required for a conventional system with a FCR of 1.0.

This would hold for a steady state production schedule in which the system recycled and fish were harvested every 8 months. In this case after a run was finished one irrigated chip basket and one submerged chips basket would be replaced with new fully loaded new baskets. Thus every chip basket would be harvested for residual wood chips, and replaced with new chips, on a 32 month schedule.

The system could also be operated on a 10 month schedule in which trout weighing 2 pounds each would be harvested every 10 months. This would require additional feed and wood chip supplement and replacement schedules but would still be functional with the given system configuration and size.

The TF1 unit is basically an indoor unit in that it needs protection from freezing temperatures and other environmental impacts. The unit can be located in a garage, barn, laboratory, green house or comparable structure. In temperate climates or for seasonal operation units can be located outdoors where they can be a part of ornamental gardens or parks.

If space is limiting a smaller 500 gallon version is available. This can show structure, process, and fish raising ability, but is generally too small to demonstrate quantifiable fish production capability.

Here are some photos of a TF1 system. These photos have a single chip basket in a four foot cube perched above the fish tank instead of the four smaller chip baskets described above.

|  |